Recycled Water Works – Oct ’14 to Nov ’20

Funds spent, 2014 – 20, on the irrigation system, drainage & improved surface of Romsey Park;

- Western Water/MRSC; $78,000 (56%)

- Romsey Golf Club; $38,000 (27.5%)

- RGC member donations; $22,000 (16.5%)

Eighty days (Oct 2014 – Nov 2020) of serious planning and hard work to plan and complete a multi-stage project. A stunning effort by the membership of

Romsey Golf Club.

Special mention, and many thanks, to Les Gaunt (Twig) and Ron Walker. Without their planning, attention to detail, hard work and dedication this project would never have been the great success that it has become.

Also to Bob McLennan and Anthony Lakey who turned up almost every day and did what had to be done.

2014

The Beginning.

In August of 2014, after years of planning, application writing and making representations to a wide range of government and private bodies Romsey Golf Club (RGC) was informed that both Western Water (WW) and the Macedon Ranges Shire Council (MRSC) had agreed to allocate all remaining funds from the “Putting Locals First” (PLF) grant (the original grant that connected re-cycled water to the Romsey Sporting precinct) to us to assist with a serious expansion to the exisiting golf course irrigation system. The existing system irrigated the greens only and used potable water.

Special thanks also to;

- Graham Treadwell, Michelle Nolte & Katelyn Stevens from MRSC and

- Kate Berg from WW.

Their ideas, willingness to negotiate and guidance were of invaluable assistance and vital to RGC completing stage one of our re-cycled water project.

- Mick Breen, Sunbury Water Life (now Sunbury Water Pros). He managed to fit the new works into the existing system for the best possible result. He was also always on the lookout for ways to make our money stretch that little bit further. His knowledge and experience were instrumental in shaping the final design of the whole project. Mick has been our first port of call all the way along. When we have ideas to improve the system Mick adds the knowledge and expertise to make sure any of our proposed improvements really did make the system better.

The remaining PLF monies (~$30,000.00) would allow us to access and utilise the 10 million litres of re-cycled water that the Macedon Ranges Shire/Western Water “Putting Locals First” grant application had allocated to RGC.

To make sure that we were able to do as much as possible the club opened a special “Re-cycled Water” bank account; a number of members deposited funds and the club itself also allocated additional monies. We knew we had a big job ahead of us but with good planning and clear communication we could attack it task by task.

Once we were assured of this funding we set to work reviewing all our plans and budgets from the various applications and deciding;

* how to best utilise the exisiting, greens only, irrigation infrastructure?

* how to get pipe, cable and decoders to all the necessary valve boxes?

* what materials (tank, pump, pipe, sprinklers, valves etc) could we afford

* could we locate additional funding?

Our first jobs were to;

* list all the materials we would require,

* locate the best supplier and order what was needed and

* mark-out and level the tank site.

With some expert assistance from John Laing, Ron Walker and Tony Lakey the tank site was marked out. Enter past club captain Andrew Clement and his tractor. He did a great job moving soil and levelling ready for the crushed rock base. The next day Jim Patton rolled up with the big truck and dropped off the granitic sand. Again Andrew set to work, this time moving the granitic sand around and levelling the base ready for the tank installers.,

“I think I can get it to within eight to ten mm, will that be OK?” he asked. Sure was! With John Boyce and Tony L along for support and guidance the site was soon levelled and granitic sand smoothed out as the final base. A few day later the boys from “Rhino Tanks” arrived and put up the tank.

This was quickly followed by the gents from Kilmore Fencing who put up the security fence. Sorry no pics.

Now, when this thing goes “Beep” we are on the money.

A quiet drink in the shade after an excellent job. Ta Andrew.

Level? this site is perfect, easy job when the preperation work is so good

Once the tank and fence were in place 75mm screenings had to be spread around the base to stop erosion. Again John Laing did a sterling job, he was ably assisted by Bruce Robb and Tony Freeman

Day one – Monday Oct 18th

Andrew Clement picked up the trencher for us and gave us, Ron and Tony L, a quick tutorial and then dug the first couple of trenches. His memory for the exact location of the 40mm blue-line ring main running down the western side of the 6th was simply astounding. A few lessons and Andrew was prepared to hand the machine over to Tony L.

Ron Walker and Les Gaunt (Twig) were soon at work laying pipe in the trenches and connecting the sprinklers and the T-joins for the water inlet junctions. Dave Muller and Tony Freeman arrived after lunch and put in a good afternoon’s work levelling and packing the sprinklers with sand and back filling the trenches.

All told we put two banks of sprinklers in the 6th, three banks in the 7th and one bank in each of the 15th and 16th. Many of these 56 metre trenches and their accompanying trenches to the edge of the fairway were backfilled.

Ron, if you push this way, it goes forward, stop taking pics and get over here and watch Tony, you’re going to have to drive this thing.

Now, that’s what I call a good trench.

Day two – Tuesday Oct 19th

Ron, Twig, Tony L Dave Muller and Bob McLennan were on the job.

Any unfinished trenches were back filled and smoothed over. We had a good yarn with Mick Breen from Sunbury Irrigation and we worked out where new pipe and decoder cable had to be used and where we could get away with just tapping into the existing blue-line ring main

We trenched, laid pipe and connected sprinkers in the old 10th and the top of the 9th and ran two banks and side trenches into the 8th/17th.

Every now and then we had to find the ring main and a deal of time was spent watching Twig and Ron using their seemingly magic bits of wire to find the existing pipe, worked pretty well too.

Dave again turned up and back filled. There was some discussion about the final of the John Laing Shield, if Dave and Twig kept this work up neither would be fit for Saturday’s match-play. (Twig beat Dave on the 19th)

Dave just loved the sound of the soil falling on the pipe, did get a bit wearing after a few hours though.

Ta Ron, this seat is a winner.

Day three – Wednesday Oct 20th

Ron, Bob, Tony L, Bruce Robb, Beryl Cole, Lorraine Robb, Wendy Gosden and Kath Jekabsons were on the job.

It took a while to sand the sprinklers and back fill and level the trenches on the old 10th and the 9th. Perhaps the longest trenches we will do.

The team then set about putting one bank into each of the 1st and 2nd. Again the “magic wire” and mattock came out when locating the pipe down the north side of the 2nd; the wire proved fairly reliable again. All sprinklers were levelled and sanded and all trenches backfilled.

A good effort on quite a warm day.

All we needed was a white dog to round up a goodly crew

So, you reckon the pipe is between the white lines hey Bob?

Day Four – Monday 24th Nov

Ron, Bob, Tony L and Andrew Laing were on the job.

All sorts of weather was predicted and that is about what we got. We began on the third. The first bank of sprinklers went in reasonably quickly then a spot of rain, a bit of thunder and some sun.

Sprinklers were connected, levelled and sanded and the blueline pipe behind the 2nd was located so we could trench the junction pipe. The 2nd bank was a different matter. The rain had continued and the ground became slippery, backfilling became much more demanding as the water infiltrated the loose soil. Then, just as we were finishing the junction trench the trencher stopped. Check this, clean that and Bob & Ron had her back up fairly soon.

All the while we could hear Twig hard at it chewing his way through the rough which had grown quickly after the previous weekend’s rain.

When the rain let up the trenches were back filled and by mid afternoon it was decided to call a halt and to hope for better conditions tomorrow.

The master gets a new apprentice

I’ll get the T Bob.

Day Five – Tuesday November 25th

Ron, Tony L and Bob were again on the job and John L turned up just after lunch to give us a hand before he headed off to mow tees and surrounds.

Twig was also out early and we could hear him cutting the rough across the course. The whole park/course is looking great, a credit to Twig’s hard work and his affection for both the club and the course. Had better refill that 44 again!

Time to clean up the 2nd. A spot of divining was required to find the blue-line on the north of the 2nd. Again the wires put us pretty close so not too much mattock work was needed.

The 2nd bank of sprinklers went in quite smoothly, trencher happily chugging away and pipe rolling out. The next bank, which will cover the 10th and a small section of the 2nd was not quite so quick. Setting the sprinklers locations to provide as much cover as possible took a while then the odd “floater” came into play. A spot of work with the mattock and the crowbar and these rocks were out of the way.

Mick Breen again turned up to explain another discovery he had made, this one should save us at least one roll of 40mm purple pipe.

Day Six – Wednesday Nevember 26th

Ron, Bob, Tony F, Tony L, John L, Beryl, Lorraine, Kath & Bruce. were on the job.

The crew were straight into it. A few extra hands made quick work of three banks of sprinklers and junction pipes.

People were busy rolling out pipe, cutting in, sanding and levelling sprinklers then back filling the trenches.

In about four hours we put two banks into the 4th fairway and one into the 5th fairway.

I tell you Beryl, if you turn the rake upside down and work off your knee it is so much easier

Connecting the junction pipe on the 5th, about 255 years experience here

We only need one bank each of 5th and on 9th/18th and two banks on the 18th to finish the fairway sprinklers.

Next week we will be working Mon/Tue/Wed, starting work at 1.00pm and going through to around 5.00 – 5.30.

Day Seven – Monday December 1st

Ron, Bob, Tony L, Mick Nicholls, Lorraine, Bruce & John L were on the job.

Again those extra few hands made the work progress very quickly and by a little after 4.00 pm we had put the 2nd bank of sprinklers int the 5th and two banks into 18. We have to run a bank at the junction of the 9th/18th.

We have enough sprinklers to put another bank into the eastern end of the 9th and a 4th bank into the 7th

Yes, a graceful curve is a thing of beauty

Just three more banks to go and stage one of the fairways is completed.

Day Eight – Wednesday December 3rd

Ron, John L, Tony F, Tony L, Lorraine, Beryl and Bruce were on the job.

Trenching the junction for the 2nd bank on the 18th and the 2nd bank on the 9th/18th proved a bit trickey but after much walking and looking at the plan all was well.

We managed to put in two banks, the 9th/18th junction and a third on the bottom end of the 9th/18th.

We now only have one more bank of fairway sprinklers to go, the 4th bank on the 7th.

Tell you what Bruce, this reminds me of that pennant match against Sunshine in ’74, we got ourselves into a mess that day too!

Just one more shovelful of sand and this one will be level Beryl

Day Nine – Thursday December 4th

A quieter day, Ron an Tony L were on the job.

Much mental gymnastics saw the north/south main line mapped out and the 10 valve boxes covering the 6th, 7th,15th and 16th worked out as well.

Oh, and we were able to trench, pipe, cut in, sand and level sprinklers and junction pipes for the 4th bank of sprinklers on the 7th. This makes 100 fairway sprinklers and associated piping now in the ground. A job well done, now to get on with the pumpshed, pump, decoder cable and 40 mm main lines.

So after nine days we have the following sprinklers and junction pipes in place;

* One bank of four on the 1st

* Two banks of four on the 2nd

* Two banks of four on the 3rd

* Two banks of four on the 4th

* Two banks of four on the 5th

* Two banks of four on the 6th

* Four banks of four on the 7th

* Two banks of four on the 8th

* Three banks of four on the 18th

* One bank of four covering the Old Course 10th and the top of the 9th

* One bank of four covering the junction of the 9th/18th

* One bank of four on the eastern section of the 9th/18th fairway

* One bank of four covering the 10th and the 2nd

* One bank of four on the 15th

* One bank of four on the 16th.

Once Skynet gets going a mower will be smart enough to do all this work on its own

Ahh, the final fairway sprinklers are in place.

Day ten, Tuesday December 9th

Les, Ron, Lorraine, Tony L, Bob and John L were on the job.

It took a while to sort out exact locations for the valve boxes and pipe for the 6th green and what will be neeeded for the men’s and women’s 7th tees. Along the way we discovered a few things.

1. Telescopic joiners are certainly not what they were cracked up to be.

2. Supposed straight lines are not always straight, this may lead you to cutting buried pipe.

We joined the purple to the blue line in the rough on the west of the 6th fairway, ran lightweight red wire to the 6th green battery timer box and marked outwhere to run pipe to the 7th tee. All trenches were backfilled.

A good afternoon’s work, especially with a few people having to duck off early.

I tell you Ron, I know exactly where this telescopic joiner should go!!

Day eleven, Tuesday December 10th

Les, Ron, Lorraine, Tony L, Beryl and John L were on the job.

We began working our way up the north side of the 7th. The extra pipe and sprinklers for the tees will come off this pipe, it will be put in place as part of stage two of the project.

John had the mower going overtime trimming the grass along the new trench lines. We ran the pipe and wire and connected the fairway sprinkler valves to the purple pipe to the two eastern sets of sprinklers. We also cut a gate valve in ready for the north/south mains line.

Again all trenches were backfilled and levelled. Beryl, Lorraine and John showed just what a spot of hard work and determination can accomplish. A trench was cut to the 7th’s top set of fairway sprinklers.

Right, first the heavy red wire then the purple pipe, have we all got that?

Western Water have been on the job too, the re-cycled water meter was connected on Wed 10th December

Our tank with its brand new security fence.

Day twelve – Monday December 15th

Ron, Tony L, Bob, John L, John Freestone, Bruce & Lorraine were on the job.

We worked our way up the 7th/14th connecting bays of sprinklers to the purple mains pipe and dug in a box for the tee sprinklers on the men’s 7th/14th and the womens’s 7th.

Final works on these, and all other tees, will be finished once we are able to finance stage two of our re-cycled water project.

John L had even built a “toboggan” to assist us to back fill the trenches. Ron, John F and Bruce had a great time working with John to find out exactly how to get the best result from this labour saving machine. All had a good time and the “toboggin” ended up being very useful.

We took the purple pipe all the way up to the ring main beside the 7th green.

In stage two we will connect from this purple pipe to run sprinklers to the 8th, 15th, & men’s 17th tees. Stage two will also see the old 10th and the women’s 17th also connected from this purple pipe

A call from Kate at Western Water saw us ordering ten “Re-cycled Water in Use” signs organised, to be picked up later in the week. Hopefully we can put these signs up in the very near future.

John F – “If we add some wings here and cut a curve there it will work beautifully”

John L – “Freebie, it is just a smudger turned upside down, now let’s hook her up and see what she can do.”

Will someone stop the car until I connect this valve box?

Day 13 – Thursday December 18th

Twig, Bob, Tony L, John L, Ron, Bruce, Beryl and Lorraine were on the job.

We began by joining the purple pipe from the 6th to the existing blueline in front of the 8th tee. A fair bit of digging and lining up to get all the joins completed.

From there we trenched up the south side of the 16th to get decoder cable to the fairway sprinklers on both 15th and 16th and up to the 15th green.

We worked out where/how to run pipe/sprinklers to the shared 8th & 15th and men’s and women’s 17th tees. Tees will be completed in stage two of this project, if and when funding becomes available.

Valves and valve boxes were fitted and all trenches were backfilled. A spot more decoder cable and this section of the course will be finished.

So, found the blueline ring main, no damage, just waiting for the water to be turned off before we connect the purple pipe.

The master touch makes sure all is well.

This junior golfer was checking out the works while mum kept a close eye on proceedings.

Day 14 – Monday December 22nd

Bob, Ron, John L, Tony L, Beryl, Mick, Bruce, Andrew L & Lorraine were on the job.

Much trickey work was successfully undertaken. Heavy red decoder cable was laid and backfilled to the 15th green battery timer box and 15th fairway sprinklers.

We spent some time working out how to get pipe/sprinklers to the 16th tee. That one will be fairly straight forward. All tees will be trenched and connected to water as part of stage two of this project.

Pull, just 1mm more and she’ll be connected

Our new “Re-cycled Water in Use” signs.

2015

Day 15 – Monday January 5th

Andrew L, John L, Twig and Tony L were on the job.

Trenching to connect the east/west line along the 7th to the ring main behind the women’s 10th tee were begun. Pipe was rolled out and the trencher fired up. All went well until the drive belt on the trencher broke.

We did get to see John driving the ute towing the trench covering machine with Andrew providing a spot of weight and Twig steering, all he needed as a whip and a mule and he could have been ploughing a field in the ’30s.

Rudi, Romsey Mechanical Services, was quite happy to come over and have a look. He later rolled up with the fork lift and took the “Brutus” to the workshop.

There has got to be an easier way to roll out this pipe!

“Happy New Year boys, now where is this trencher?”

A spot of rope, a block of wood and you can do almost anything with a forklift.

Day 16 – Monday January 12th

Twig, John L, Andrew L, Bruce, Lorraine and Tony L were on the job.

With purple pipe sticking up in the middle of the 18th fairway it was decided to continue the north – south run from the 7th fairway to behind the women’s 10th tee. The end of the run was in sight and all was going swimmingly when we smelt hot rubber, seconds later the belt that drives the digging chain disintergrated.

Tony L was quickly over to Tom O’Deas for a replacement but no luck there so a web search found DitchWitch in Campbellfield. A call, some revisiting the machine to check on details and some extra belts were ordered.

The missing belt was replaced on Tuesday afternoon and all was ready to go for Wednesday.

Some “Old Hands” have a go at unrolling the purple pipe.

Just about got the trench backfiller under control.

Tony F works to replace the damaged drive belt.

Day 17 – Wednesday January 14th

Bob, Bruce, Twig and Tony L were on the job.

The north-south line was completed and connected, with gate valve, to the blueline ring main.

From there we headed back to the east-west line along the 7th. We trenched, laid pipe and red cable, connected fairway spriklers down the 8th, connected the 1st bank of fairway sprinklers on the 6th.

Light red cable was also run to the battery timer box at the back of the 8th green

A couple of “Old Stagers” getting on with the job.

“OK, we’ve done this a few times now, doesn’t seem to be any easier!”

Listen you lot, when I’ve finished it will look like these boxes grew here.”

Day 18 – Thursday January 15th

Bob, Ron, Tony L and Twig were on the job.

We planned to run a pipe and cable from the north-south main up through the 9th fairway and passed the 9th and 18th greens to connect to the blueline ring main.

Along the way we connected four banks of fairway sprinklers on both 9th and 18th and also trenched to the existing battery timer boxes that control irrigation on the 9th and 18th greens. Only slipped the digging chain off once but our experience from Monday soon saw everything re-connected and working again.

At last a system, Twig, you push, Bob, you pull and I’ll feed it in.

We flushed the purple pipe before connecting to the ring main.

Ready to connect to the blueline ring main

Day 19 – Monday January 19th

A big day with plenty to do. Twig, Bob, Mick, Ron, Tony L, Andrew L, John L, Bruce and Lorraine were on the job.

Light red cable was connected to the 9th and 18th green battery timer boxes and the trenches were backfilled. Next an east/west trench from the purple pipe that runs north/south through the centre of the course. This new pipe picked up the two sets of fairway sprinklers on the 5th and the 1st set on the 9th/18th. We also ran light red cable to the existing battery timer box on the 5th green

A deal of time was spent designing the best way to get water to the women’s 9th tee, the shared 18th tee the men’s 9th tee and the women’s 6th tee. These tees will be trenched and connected to water when we move into stage two of the project.

We also walked, measures discused etc the best way to get heavy cable to pick up the sprinklers on the 2nd and 3rd fairways, the women’s 3rd tee and 4th tee and the men’s 3rd, 4th and 6th tees. All in all, much accomplished.

Well gentlemen, it seems we have found the old blueline ring main behind the 5th green.

Now Ron, this one goes to the 5th green and that one to the 1st set of fairway sprinklers, right?

Only the truly experienced can produce such a very neat job when backfilling a trench.

Day 20 – Tuesday January 20th

Bob, Twig, Tony L, Ron and Lorraine were on the job.

We trenched from the north-south line up to the blueline ring main behind the 4th green

On the way we picked up two banks of fairway sprinklers and the 4th green battery timer box. A faulty join on the north-south line was also repaired. A gain a deal of time was spent designing how to get water to the men’s 5th tee, shared 12th tee and the women’s 5th tee, in the end a can of line marker. To be completed as part of stage two.

Once all was connected we had a look at the fairway sprinklers. The certainly looked good even with the strong northerly wind. Certainly great to see the works so far have been sucessful so far.

OK everyone, this is our last roll so let’s get it right.

Bob adds the finishing touch with the crowbar

Yes, after all that work the fairway sprinklers work.

Day 21 – Wednesday January 21st

Ron, Twig, Tony L & Bruce were on the job.

As we trenched, laid pipe, dug in valve boxes etc the ladies worked their way around the course with vague promises of coming back after their round to help backfill. We trenched from the battery timer box on the 5th green across to the 2nd green and then down to the battery timer on the 3rd green. Heavy decoder cable and light red cable was laid.

We then trenched across to the blueline ring main to pick up the 1st set of fairway sprinklers on the 3rd, from there we followed this blueline further up the north side of the 2nd to pick up both sets of fairway sprinklers on the 2nd and the 2nd set on the 3rd fairway.

Best let them putt out before I trim up this hole

Yes, now we now where the old blueline runs.

“Brutus” takes a rest in the shade after a big morning’s work

Day 22 – Tuesday January 27th

John L, Lorraine, Twig, Bob, Tony L, Mick and Ron were on the job.

There was some back-filling from last Wednesday to tidy up then we began finishing off the fairway sprinklers on the 2nd and 3rd fairways. There was much discussion re planning for the men’s and women’s 3rd tees. It was decided that, when stage two gets going, these tees would both come off the one decoder operated timer.

We walked the 1st fairway to sort out where to connect from the pump to the blueline ring main. The huge trees around the tank will certainly mean serious root problems. We also had to trace the blueline up the south side of the 1st fairway, no more hitting that pipe.

Just as we were leaving we came across a couple of battery timer operated valves that had become jammed open, carefully unscrewing the tops showed pieces of plastic from out saddle joins. No doubt we will have a few more of these before all the detritus in the lines clear.

Twig & Mick Snr finishing off the 2nd fairway sprinklers

John L takes care of tree roots on the 3rd

So, all that’s left is one on the 10th and one of the 1st?

Day 23 – Wednesday January 28th

Twig, Tony L, Bruce, John L and Ron were on the job.

We set about placing the purple valve boxes over all the uncovered valves across the course. We also placed a number of smaller boxes over gate valves and pipe or decoder cable joins.

There was much discussion re how best to get the 80 mm pipe from the pump to the ringmain. In the end we decided to call in the expert, Mick Breen (Sunbury Irrigation) to point us in the right direction. Some trenching was done and Brutus slipped the digging chain drive chain. After some investigation we located the problem and soon had it fixed.

After a briefing session the crew heads off to work.

John’s design, the quickest way to backfill any trench.

Day 24 – Monday February 2nd

John L, Mick, Twig, Tony L and Bob were on the job.

After much thought and discussion we sorted out exactly where the 80 mm pipe from the pump was to meet the 40 mm ring main. We had to attach a couple of valve boxes and run pipe up to the 1st fairway sprinklers. Light cable had to be run the the exisiting battery operated valve box on the 1st green.

There was also much discussion as to how we were to get water to the 1st, 2nd and men’s and women’s 10th tees. Again these works will be done as part of stage 2 of our project.

If you were wondering we decided that the 1st and men’s 10th would run together and the 2nd and women’s 10th would run together)

What do you think John, bring the 80 mm in through here?

Yes Mick, this is definitely the last trench to backfill, that is until stage two.

It’s going to get crowded once we join up the 80 mm but we’ve got it under control.

Day 25 – Monday February 9th

Twig, Tony L, Bob and Ron were on the job.

The day began with a visit from Mick Breen (Sunbury Irrigation) who walked us through the orientation of the shed and pump and how to connect the 80 mm pipe to the 40 mm ring main.

We also had a visit from a representative from Rain Bird who talked us through how to join the heavy decoder cable and the light red cable. Twig took it all in, we will just do what he says and there should be no problems. Stage two will see a central Rain Bird controller put in place in the pump shed.

From there it was into the ovals’ tank enclosure to sort out how we would get Brutus unside to dig the trench and where we would run our power line. We decided on heavy sleepers and Brutus’ own ramps and numerous barrow loads of scoria to get him up and over the existing pipework. A spot of adjustment here and there and he was over. Ron then had to head home to take care of a European Wasp problem. This trench saw the digging chain come off once (not a problem we are getting good at this one) and the drive chain also clag up (again, we are getting good at this one too). A few roots here and there but excellent axe work from all three of us and the trench was completed.

The trickey part now was to get Brutus through the narrower gate into our tank area. A spot of ducking and weaving and he was in. Again a few root problems but in the end the power trench was completed and the trench for the 80 mm pipe out to the ring main was started. We will need a heftier maching that Brutus to do the rest of that trench. All in all a very good day’s work

Brutus’ bridge over the water-pipe to trench the power in.

Well Bob, I think we cut the power in here and begin the trench near your right boot.

Yes, we had to deal with a few more roots

Day 26 – Thursday February 12th

Ron, Twig, Tony L, John L & Bruce were on the job.

Twig got to work connecting the power and feeding the cables through conduit before laying it. The rest of us got busy backfilling the trench, Twig carefully placed the required warning tape.

The shed slab was measured, framed up and levelled. Reo was purchased and concrete ordered. Of course Bob had also been busy dropping off stakes and trowels in preparation for the slab works.

On Wednseday the tank was connected to the re-cycled water meter so we really are getting towards the business end of this whole process.

Local rule 47B; club life members always get first go on the shovel to clear any concrete related site

Twig brings the power feed into our tank enclosure.

The shed base, framed up with power supply almost ready to be made live.

Day 27 – Friday February 13th

The day began with a meeting in the clubrooms, Graham Treadwell and Katelyn Stevens (MRSC) met with Ron, Twig and Tony L to discuss power meter location and associated bits and pieces. It was a good meeting with both sides happy with the morning’s discussions.

Bruce and Lorraine joined us to put down the concrete. Just on midday Trevor, from Gisborne Garden Supplies, drove the mini-mix down to the tank. He could tell how much to put in the barrow by just looking at the barrow pusher! About eight barrow loads later and he was washing down the shutes and heading for home.

Ron, Twig and Tony L screeded and trowelled the slab and even used a spot of excess concrete to make a step in front of the door. Whilst Bob was not present he was well represented by various stakes and two trowels he had dropped off earlier. All in all a good day’s work.

Trevor had a good eye for an exactly filled barrow.

Twig & Ron set about screeding the slab

Job done boys, hey, look away for a second and someone scribbles in the concrete.

Day 28 – Tuesday February 17th

John L, Ron, Tony L & Twig were on the job.

First off arrange and assemble the main connection bringing water from the 80 mm pipe to the 40 mm ring main. A spot of priming and glueing then some careful, accurate cutting to make sure everything fitted and was water tight.

Then onto the fairway sprinklers. The first 40 sprinklers we put in did not have the nozzle inserted. This nozzle dictates how much water is allowed through the sprinkler. A spot of kneeling twisting, lifting, inserting and then tightening and we were well on the way to fixing all 40 sprinklers. Ron took most of this work.

Next we had to walk the system to work out just where to place the 120 cm copper earth-rods. In all we will have 12 around the course and three in the shed protecting the pump. During our perambulations we came across one joiner that was leaking, a spot of work with the stilsons and all was well again.

The old fittings were taken out and the pipes drained ready for the new 80mm to 40mm fitting to be installed.

Our new fitting in place and under pressure, so far, so good.

Simply insert the screwdriver, turn and lift then insert the No 4 nozzle, and tighten the holding screw. After a few sprinklers Ron had it under control, pretty bored by sprinkler 100!

Day 29/30 – Thursday 19th & Friday 20th February

Ron, Bob, John L,Twig, Bruce and Tony F were on the job.

Ron began on the fairway sprinklers. Each had to be checked to make sure it was on the correct angle and then to make sure that it was spraying the full 360 Deg.

Twig set about installing the earth rods, and joining and sealing all the wires.

Bob, John L, Bruce and Tony F lugged the shed up to the tank and set about putting it together and bolting it down to the slab.

All in all a good two day’s work, shed looks great and once you open one of the purple boxes you get to see just how much work Twig has done and also his attention to detail.

Bob sets about screwing the roof down

These boys were so chuffed with their work that they were talking about entering the shed building game. From the left, actual worker (Bob), hired muscle (Tony F) and supervisor (Bruce).

Day 31 – Monday February 23rd

Ron, Tony L and Twig were on the job.

Another warm day so Twig began at 7.30 am, Ron, working on the principle that the sprinklers would keep him cool, turned up a bit later. Tony L was busy dragging away the branches that had fallen over the last few weeks.

Ron finished off the final banks of fairway sprinklers. Easily kept his cool.

Twig finished off the final dozen or so purple boxes then had a good look at the shed to work out exactly where to site the switchboard, meter, switches etc.

Day 32 – Tuesday February 24th

Twig, Ron, Tony L and John L were on the job.

John F and Bruce dropped in to help out as well. First thing, mark out a line for the new trench .

Twig finished off the power in the shed, there was a minor hiccup but after much thought and checking it was solved. A bit of running around to get a backing board (900 mm X 900 mm) but all was good; meter installed and plenty of room for the Rainbird sprinkler control centre, when it comes

.

We had a small leak from the 75 mm gate valve so a quick search produced two sets of stilsons, one borrowed and one bought. Some “Stag” applied to both surfaces and all was well.

Ron and Tony L got into some of the larger roots close to the fence, a spot of axe work and all was well. Brett Lockens “Locko” turned up with his excavator and put on a clinic in the clean digging of a gracefully curved trench.

Next item the priming and glueing of each length of 80 mm pipe. A little trickey when the wind blew up but not really too difficult. Apply primer to both surfaces, glue on both surfaces, insert, push pipe home and hold for a count of 20. Trenching and priming/glueing just about kept pace with each other.

Then lay the heavy de-coder cable back to the pump shed and cover over with purple “Re-Cycled Water, Do Not Drink” tape

Locko was even gracious enough to pull most of the soil back over the pipe and cable

The 80 mm pipe and trenching line ready for the excavator

“Something borrowed something new” soon saw the gate valve undone, resealed and tightened.

Twig begins priming & glueing while Locko keeps trenching.

Pink primer on now for the green glue.

John and Bruce check out the final length of pipe.

Ron, John L, Twig & Bruce, just after 80 mm supply is connected to the on course piping. Job well done gentlemen.

Day 33 – Friday February 27th

Bob, Twig, Tony L, John L, Tony F, Ron & Bruce were on the job.

First, unpack the pump and haul it into the shed then line up the pump inlet and the tank outlet and cut a hole through the north wall of the shed.

Second, line up the pump outlet and the pipe out into the course and cut a hole through the south wall of the shed.

Third, cut lengths of 80 mm pipe to fit then prime and glue.

Fourth, bolt the pump to the slab.

Fifth, plug pump in and turn on.

All went well until we turned on the pump, the 125 psi was a little too much and the final elbow began to leak, pump quickly turned off. Nothing serious just a minor setback. Need a new connection to the pump and a new 80 mm elbow.

After a quick call to Kate (WW) we now have the “Site Management Plan” and the “Drinking Water Disconnection” paperwork to attend to.

Bob makes sure all is level before connecting the tank to the pump.

The pump in place

The final stage of connecting the pump to the 80 mm out onto the course

Finally the supervisor had had enough, “This, gentlemen, is how it’s done!”

Day 34 – Tuesday March 17th

Ron, Twig, Tony L, Bob & Bruce were on the job.

A visit from the Rainbird rep to check our cable joins, the way we have set-up the valve boxes, explain how to fit and connect the decoders and to discuss the central controller. This controller will be the brains that runs the system,

RGC has written to the Macedon Ranges Shire Council outlining our plans for stage two and providing a budget for material and related works (including the central controller and the decoders that tell the valves when to open and when to close so that irrigation occurs both at the correct times and for the correct period of time). We have asked that MRSC consider our applicaion when they are drawing up the 2015/16 budget.

In the meantime, once we have disconnected from mains water and turned the re-cycled water on, we will be relying on our current battery operated timers to turn water on and off on the greens and a few banks of the new fairway sprinklers.

So after 36 days of steady work we are just about ready to turn a somewhat abbreviated system on.

Day 35 – Friday March 20th

Ron, Twig, Tony L, Bob & John L were on the job.

The big day, disconnection from drinking water and the turning on of the re-cycled water.

Kate and Trevor (WW) arrived and we went through the “Site Management Plan ” and the “Disconnection from Drinking Water” paperwork.

Then an inspection of the exisiting blueline main from the water meter. This line was cut and closed off so that re-cycled water can not mix with mains drinking water. So, now disconnected from the mains, we opened up the valves on the tank and ran the pump. The existing battery timers worked well and all greens were irrigated. Work on a few “spare” battery timers saw some of the banks of fairway sprinklers also working.

We will investigate the viability of moving these fairway battery timers around so that more of the fairways get a drink.

A spot of purple paint and all is good.

The pipe to the mains is cut and sealed before being reburied.

Day 36 – Friday May 11th

Greame Walker, local plumber, and Tony L were on the job.

The negotiations with Western Water now saw us locating the connection to the mains and then digging down about 600mm to disconnect it.

A great morning for work, freezing southerly wind, hail and then drizzle. To cap it off the pipe was 32mm not 40mm as we had been advised so off to the suppliers to pick up the 32mm cap. Once the pipe was capped off we disconnected the meter ready for return to Western Water.

Graeme brought his version of the crow-bar. Certainly made things easier and quicker.

The mains is cut and capped

Now, let’s get this meter back to Western Water.

$10,000 funding for stage two was included in the 2015/16 MRSC budget. Unfortunately it is now too wet and too cold for our somewhat “experienced” workforce to re-start works until spring. We would like to thank the our MRSC councillors, especially Ian Ellis, Henry McLaughlin and Mayor Jennifer Anderson for their support and trust in us to spend these monies well.

Stage two of this project will see;

1. Decoders added to all green and fairway sprinkler valves

2. A central control unit put in place in the shed to operate the decoders.

3. Additional piping run and sprinklers added so that all tees are irrigated, decoders will be added to these valves.

4. Up to seven additional banks of fairway sprinklers put in place.

5. Additional tapping points to irrigate existing and new garden beds around the park.

Day 37 – Wednesday May 27th

John L, Tony L, Bruce and Ron were on the job.

Our fairway and other trenches had seen many visits from rabbits who left numerous scratching of varying depths. The autumn rains had also seen the loose soil begin to settle so some backfilling had to be done.

Over to Frontier Garden Supplies for two metres of soil and then out onto the course. Plenty of shovelling, walking to and from and raking was involved. The trenches took a surprising amount of soil and we were soon back for another metre and a half to get the job was finished.

It was a beautiful autumn day and whilst repetetive the work was not overly strenuous so all enjoyed the activity.

What a crew, Ron on a 106/27 visa – “Specialist Rake Operator” – and two locals looking to learn the trade but happy to start an the bottom and work their way up.

Day 38 – Monday July 21st

Twig and Tony L were on the job.

Work on the irrigation of the tees got underway. With the trencher away this work had to be done by hand. Luckily some reasonable rain over the preceeding weeks saw the soil reasonably soft so the work was not too difficult. The run of pipe to the tee was also quite short so not too much trenching was required. After sorting out the joiners, reducers, extenders, the sprinklers and the teflon tape we were away.

Cutting a T-join into the 25mm green-line

No beauty in a straight line

The 2nd and final tee almost complete

The central electronic controller is put in place, now to disconnect the manual timers and put the new valve decoders in place .

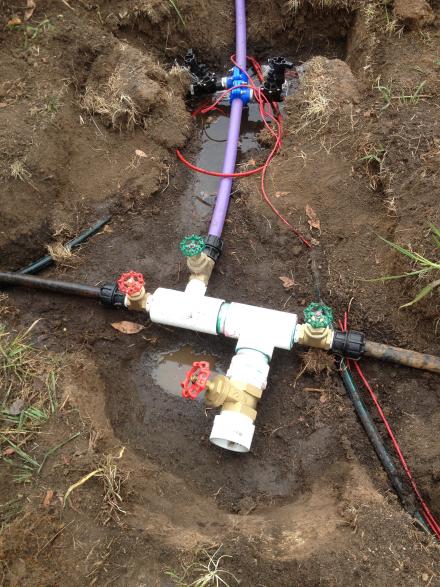

Earth rod, sealed cable joins, saddle join, valve and decoder, getting a bit crowded inside the valve box now.

Now, only five extra banks of fairway sprinklers to go in. Will have to wait until after the Club Championships in September then back on the job.

Day 39 – Tuesday November 17th

Twig, Ron and Tony L were on the job.

Freebie and Tony L had picked up the trencher the day before so all was ready. Out and on to the 8th, two banks to go in. Brutus purred away happily (JB had done a great job fixing bits here and there), the soil still showed quite a bit of moisture. The first trench and connection to the blue-line went in well. As we approached the last third of the 2nd trench a new sound caused us to lift the digging arm to inspect for a jammed stone. Nothing there but the noise was soon identified as the drive belt slowly coming apart. With care we nursed Brutus through the remainder of the trench than ran the trench to the blue-line, all very surprised that the belt actually lasted this long. Sprinklers connected and sanded and valves connected and Brutus back to the shed. A spot of back-filling and then a test, both banks put out a strong and steady flow of water.

We still had two spare DitchWitch belts in the shed so time for well known belt replacer and RGC captain, Tony Freeman, to put his previous experience into practice. Tony L took guards off, manhanded tools and leant some muscle where and when needed. Took just 20 minutes this time and we are getting better at this. All ready for the next day.

Ron, eager to get the 4th last bank underway

Just leave the detailed work to Twig.

Do you reckon he can get Brutus between the truck and the tree and over here to the junction box?

Day 40 – Wednesday November 18th

Twig, Ron, Tony L, John L, Tony F and Bruce were on the job. Elaine Scanlon provided a great morning tea. Bruce, Pam Drummond, Lorraine and Beryl worked the rakes in the cool of the evening to finish off the backfilling of the trenches.

After years of planning, application writing and presenting to various bodies this all important project was approaching a successful conclusion.

The actual on course work has taken just over 12 months now stage one (Fairway and green’s sprinklers) and stage two (tees, electronic valves and central control system) are virtually done.

A trench and sprinklers on the western end of the 4th and one on eastern end of the 4th and it was almost over. Fit then level and sand the sprinklers before the “smudger” was back in action. Certainly a lot easier on the back than backfilling with rakes and shovels. With Ron driving, Bruce acting as chatty ballast, Tony F lending a certain gravitas to the situation and Tony L keeping the smudger on line we did a basic backfill of all trenches.

We now have;

* One bank of four on the 1st

* Two banks of four on the 2nd

* Two banks of four on the 3rd

* Three banks of four on the 4th

* Three banks of four on the 5th

* Two banks of four on the 6th

* Four banks of four on the 7th

* Four banks of four on the 8th

* Three banks of four on the 18th

* One bank of four covering the “Old Course 10th” and the top of the 9th

* One bank of four covering the junction of the 9th/18th

* One bank of four on the eastern section of the 9th/18th fairway

* One bank of four covering the 10th and the 2nd

* One bank of four on the 15th

* One bank of four on the 16th.

* The old mains water supply disconnected and meter returned to Western Water.

* All tees irrigated

* Tank, fenced enclosure, pump and pump shed installed.

* Power connected to the pump shed.

* 90 mm pipe from the pump to the 40 mm ring main/40 mm purple pipe junction.

* Central control system in place.

* Decoders on every control valve.

* All paperwork with Western Water filled out and signed off.

AND

* A park/golf course that is much greener and more attractive to community members and native fauna alike.

All in all a stunning effort by this group of volunteers. A little over 40 RGC members have had a hand in this project. Now let’s see the system run for 12 months and then decide if and what additions/alterations we have to make.

Well done one and all.

On the 5th where the 40 mm purple pipe runs across the course to connect to the old 40 mm Blueline. Now, dig very carefully, find the purple 40mm pipe, DO NOT hit the thick red cable! Then we can run the 25mm green-line under them both.

First, locate the sprinkler then level it off and backfill with sand.

With Twig already off on the fairway mower and John L off to a meeting this bunch was all that was left to photgraph, Tony Freeman, Ron Walker and Bruce Robb. Well done gents.

2016 May

After almost 12 months of irrigation we now know just how involved this whole process is. We have tried a number of different regimes to irrigate the course and have finally settled on one that works. We have also discovered that the 10,000,000 litres of re-cycled water that was allocated to us is nowhere near what is required to keep the course green for most of the year. Our records show we used all that during the months November to March.

We are currently in discussions with Western Water about increasing this annual amount of water and about increasing the inlet pipe from 25mm to at least 40mm. We are also looking into running a second pump to make sure we can get the required amount of water out on ot the park each irrigation night. The second pump will allow us to run more banks of sprinklers at the same time. We will also change the current sprinkler nozzles to allow for a larger spray of water.

If we are successful in getting an increase in our annual re-cycled water allocation, in increasing the size of the inlet pipe and if we get the pump and larger nozzles in place we will then have to make sure that we can get the required amount of water in to the tank each night. This is especially the case during the hotter months of Nov – March, when everyone else is looking for re-cycled water as well. Not as simple as some might think.

In late 2016 we were successful in increasing our annual allocation of re-cycled water from 10 Megalitres to 14 megalitres, 10 Mg high season and 4 mg low season. In September of 2017 Western Water informed us that the connection and water meter would be increased from 26mm to 32 mm, so more water more quickly.

2017 November.

The re-cycled water inlet was increased to 32mm in late 2017. This gave us a flow rate of about 8 litres per second. WW contacted the club re taking additional water. After discussions it was decided that we should prepare a document to outline the current situation and specify what would need to be done to allow us to take additional water and deliver to the course. WW has was given document and they are considering it. We do not expect to hear back from them until the middle of 2018.

Well, nothing what so ever from WW so off we went again.

2018 April

We had a stroke of luck in early 2018 when the MRSC contacted us to say that they did not have any more use for the bore within Romsey Park. They inquired as to whether we, RGC, might be interested in taking over the license and the annual lease. We gave a very considered “Yes” and then completed the necessary paperwork and required payment. The bore and ~10Mg of water pa was ours. The big problem was we did not have enough pump power to get enough water out on to the Park in the time allotted to us for irrigation.

Between May and August 2018 we were busy applying for funds to expand the irrigation system.

First off was the Bendigo Bank’s Community Investment Program. We applied for funds to purchase and instal a second pump so as to provide the power to get the water out on the Park.

Second was to local MHR Rob Mitchel for funds to expand the irrigation infrastructure so it could handle the increased output of the 2nd pump. Both grants, to varying degrees, were successful. Hugh Drummond and Tony L did a great job here. With money from the club we would be just about able to hire the trencher, buy all the 25mm, 40mm, & 63mm pipe, necessary fittings and glues etc and get everything either in the ground or in the pump shed.

Ron (Planner and organiser extraordinaire) and Twig (Gifted artisan) were quickly on the job, working out how and exactly where to instal the 2nd pump and consulting with Mick Breen at Sunbury Water Pros as to exactly where additional piping, sprinklers, decoders etc had to be placed.

Day 41 Friday December 14th

Ron and Twig were on the job.

With heavy rain at the end of the week, more predicted over the weekend and cool, slightly wet conditions predicted for the following week this was the perfect time to get on with the job. The glue would take 48 hours to harden and cure so conditions were perfect to turn off irrigation system for a few days. The main distribution box was dug out and a new manifold fitting was designed and measured up. The route for the 63mm pipe was walked and all exisiting piping located and uncovered. Cutting a pipe would be OK but cutting the heavy red cable cable was a definite NO! These initial works would be vital for the successful laying and connection of the 63mm pipe.

Day 42 Tuesday December 17th

Ron, Tony L and Twig were on the job.

The water was turned off and the new manifold fitting was checked for size. The route for the 63mm pipe was mown and a few “Jumping Jacks” ants’ nests along the way were dealt with. The manifold was cut to size and glued in place. All was good for the trenching.

One of the exisiting pipe and cable points we had to go under.

Twig with his brand new manifold

Twig & Tony fit the manifold

Everything in place ready for tomorrow’s trenching and pipe laying

Day 43 Wednesday December 19th

John F, Bruce, Lorraine, Tony L, Twig, Ron & Scott were on the job.

The 63mm line was trenched, tricky here and there where we ran up against existing pipe or the dreaded RED CABLE but we made it. Next introducing a loop to improve water flow and pressure to the 15th. The route was walked and exisiting piping and cable uncovered then closely mown. We had to find the blue-line ring main at the back of the 16th. After a few exploratory holes nothing was to be found so we left it to Brutus to do this job. After about 5m we hit pipe, marked it and then dropped the depth. A further 5m along we hit the blue-line ring! So there you go. Trenching the remainder was pretty straight forward apart from negotiating the red cable and the ring main but all was good. The purple 40mm pipe was rolled out, (thanks Twig & Ron) and we were about 40m short. A spot for the connection and decoder to irrigate the practise green was dug out and the route to the green walked, mown and trenched. Ron was off to Sunbury Water Pros to pick up the two rolls of purple 63mm and one of purple 40mm pipe ready for the next day’s work. A big day with much accomplished.

Meanwhile Hugh chugged around the greens putting out X spray with a spot of Y and Q mixed in, greens still looking excellent. John L was also about mowing tees and surrounds. Place looks good John.

Again, a graceful curve is a thing of beauty.

Twig & Ron clean near the existing pipe and cable

Trenching from to the ring main behind the 16th back the 15th.

Day 44 Thursday December 20th

Bruce, Twig, Ron, Tony L, John F, Scott, Lorraine and Wendy were on the job.

Twig was on the spot early making sure a few of the simpler fittings were in place and watertight. The extra 40m of 40mm purple went into the 15th quite easily and all connections were soon in place and watertight. Again Twig did the tricky stuff, Tony, Bruce & Ron just supplied the muscle to drag things around and hold them in place.

Ron had the rolls of 63mm pipe ready to go. The 63mm was both heavy and cumbersome, two of these big rolls would require a real of effort. We discussed various ways of unrolling it beside the trench then Twig had a brilliant idea. We lifted the roll on to Ron’s trailer and with Tony, Ron & Bruce rotating the roll Twig, Scott and John F were able to drag the pipe out. Being a cool morning the pipe was not at all happy to bend but with a bit of man-handling we were able to connect it to the manifold. The 2nd roll went pretty smoothly fitting under some fairest piping and connecting into the 40mm purple at two points. Twig also fitted a valve and decoder for the practise green irrigation.

Tony, Bruce and Scott then applied the John Laing Esq patented trench filling-in technology. This little invention did a great job dragging about 80% of the loose soil back into the trench. Ron, Bruce, Lorraine, Scott and Wendy did a sterling job raking any remaining soil on to the trench line.

So, now to test all our work, took some time for the system to pressurise and when it did we found two small leaks. Will see how they go, they may take up.

The damaged blueline ring main behind the 16th is repaired.

The old team, Twig & Ron, at it again connecting to the blue line just below the 15th

Well, she sure is big, how are we going to handle this?

You two turn and I’ll drag.

Freebie and Scott came along to help out, by this time Twig was having trouble taking things seriously.

The 1st 63mm into the 40mm join – 4th fairway

The 2nd 63mm into 40mm join – sth side of 5th fairway

The John Laing patented Trench Filling Technology in use, Bruce clearing and Scott providing navigation.

Ron, Wendy & Lorraine finish off filling the trench.

Day 45 – Friday December 21st

Scott and Tony L were on the job. Simple enough work, roll out the 25mm pipe. Connect to the decoder and valve, cut in a T-join and three connections for sprinklers, connect the sprinklers then back-fill and test. A spot of raking and back-filling the trench and all was ready for a test.

Piping connected to the decoder and valve box.

Scott hard at work finishing off the trench

There you go, water on, no leaks and all sprinklers working well

2019

Day 46 – Monday January 21st

Twig, Tony L, Ron & Hugh were on the job.

A few days earlier Ron had picked up the 2nd pump and he, Tony and Twig had man-handled it into the pump-shed.

Connecting the 2nd pump to the system took a great deal of thought and planning (Ta Twig). We had to put a T-piece into the inlet pipe and then cut precisely so that the new piping was level and lined up with the new pump. The tricky part, at the inflow and outflow ends was connecting to the elbow while also connecting to the barrel union on the pump. Measurements were taken twice before any pipe as cut. Primer and glue were applied and each join was tackled one by one. With quick-drying glue it was very tricky and the odd last minute change had to be made to allow pipe to be lifted up, slid into the elbows and then quickly pulled back a few mm and tightened to the pump at the barrel union join. There was a spot of tin cutting to allow for the elevation. Under great duress everyone held their cool and the job was done. Allow 24 hrs for the glue to harden and cure and we were able to have a test run on Tues 22nd.

Our 2nd pump, finally in the shed, just waiting to be connected to the system and bolted to the concrete.

Cutting in on the outflow side.

Cutting in on the inflow side

Ron, Twig & Hugh. Everything connected, 24hrs for the glue to dry and cure and we will give her a go.

And there you go, two pumps, side by side, just waiting to get on with the job.

So, after many years RGC now has a pretty good irrigation system. We know we need to add more sprinklers here and there and more 63mm pipe to make sure we get additional pressure into he system but, like most things, that will have to wait until we have the money. A huge thank-you to all those RGC members who have given up so much time to see these works through. Your hard work and dedication are what makes our club so special.

2020

Day 47 – Thursday June 25th

After discussing our failed submission of 2019 we decided to go deeper into that project and submit a very detailed application to the MRSC 2020/21 budget process. The application is for a three stage program to vastly improve Romsey Park, making it safer and more usable for the whole community while also improving the Golf Course. The three stages were;

- Levelling and drainage works to get water away and make the whole park safer.

- Additions to the irrigation infrastructure to greatly reduce friction and get more pressure into the system thereby providing far better ittigation

- Sowing of couch grass sprigs into all fairways and reducing the amount of water we need to keep the fairways alive during summer.

A great job by the Greens’ Committee, special thanks to Mal Mottram, Tony L, Ron W and Hugh D. We will see how we go.

Day 48 – Wednesday July 8th

Tony, Mal and Ron represented the club in a Macedon Ranges Shire Council Zoom meeting.

This was before all the councillors and we were able to make a three minute presentation and then answer any questions the councillors might have. Those involved felt the presentation had gone well.

Members of the committee also made a few follow-up calls to various councillors offering to answer any questions and giving whatever informations we could. The big date was Wednesday July 22nd when the councillors would propose an amendment to ve the MRSC 2020/21 budget. If this amendment was made and subsequently approved then we were on our way. We had no way to know if all or parts of our application would be added tot he 2020/21 budget

Day 49 – Wednesday July 22nd

Unbeknownst to most members of the club the MRSC meeting was available on line and the few RGC members who did watch were extremely happy when the amendment to include our project into the 2020/21 budget was moved and approved, unanimously. A few phone calls later, thanks Hughie, and all the Greens’ Committee was aware of our success. Other members of the club received an Email informing them of the success of our application on Thursday 23rd.

Our application; RGC-3StageFairwayProgramFinal

Now the work begins, but what a great project for the future of our club.

Day 50 – Wednesday August 19th

Ron, Freebie, Tony L and Bob were on the job.

An early phone call, (7.00 am!) let Ron know the pipe was on its way. Freebie and Tony quickly headed down and unloaded on Park Lane rolling the pipe inside the fence. The Park was way too wet for the truck to get anywhere near the shed. Later in the morning Ron, Tony, Freebie and Bob carted the pipe down to the shed. All is ready for the trenching, just have to wait for the place to dry out a bit!

So, its off the truck, happy now?

There, safely inside the fence

Just one more load after this.

Day 51 – Wednesday September 8th

Cam Newnham, Tony L, Mal Mottram and Ron W were on the job

A slow and steady walk around the course to look at each section of the approved works. A spot of fine tuning here and there and a bit of amazement with just how quickly Cam could sum up a problem and provide two options for us. If the weather holds and the course dries out then works could begin in early September

Cam points out the solution

Day 52 – Thursday September 9th

Special thanks to Mal Mottram who agreed to take responsibility for the drainage, filling and levelling works.

Cam, Mal, Tony L, Bob McL, Ron, John F, Clive Mensforth, Scott were on the job (plus the NewEarth boys)

Time to get the show on the road. First set up the laser level, then mark out the route for the drain and start digging. As soon as the soil was taken out the water flowed in. The area to the north of the 4th fairway and west of the 10th fairway has ben extrenmely wet and this new drain will move that water into the top dam.

A second drain below the top dam, moving to the east and towards the bottom dam also had to be widened and reshaped. All the drains will be wider with more a gentle batter so that we can mow them without damaging the mowers. Along the way a few branches had to be trimmed to allow the excavator through. We found a turquoise pipe that no-one knows anything about and had our first casualty for the day. One section of heavy red cable running from the 5th green to the back of the 2nd green was cut. No real problem, RGC, like most sporting clubs, has members from every trade and profession so Darren Newnham on the job tomorrow to repair the cable.

The drain above the top dam begins

The water logged soil sees the drain begin to fill

Trimmed branches ready to go to the pile

The drain below the top dam begins to take shape

No-one knows anything about this turquoise pipe

The one and only casualty for the day however, easily fixed, Ta Darren.

Day 53– Friday September 11th

Mal, Tony L, Cam, Andy & Matt were on the job.

First thing; finish off the two drains into and out of the top dam. Second thing; put in the new drain out of the bottom dam, put some cross-overs in place; then let the water flow. Everything worked well and the area around the 4th and 10th fairways began to drain well and started to dry out. Next on the agenda, shallow out and shape the drain across the 4th fairway so that water actually drains into the top dam. Not so easy but made to look easy, finished drain a thing of beauty.

Work begins on the 4th fairway drain

The finished article, far wider with a more gentle shape

The drains work, water from both top and bottom dams flows into the large N/S drain along the eastern boundary

Day 54 – Tuesday September 15th

Mal, Tony L, Cam and Matt were on the job.

A few branches had been trimmed to allow the excavator to repair and widen the N/S drain along the eastern side of the 6th fairway. This was linked into the E/W drain across the 6th near the work shed. Work also began on the drain off the 7th into the large eastern drain

Work on the drain across the 6th commences

The N/S drain along the 6th repaired and ready to carry water.

Day 55 – Wednesday September 16th

Mal, Tony L, Cam, Steve Wilkins (Sevi) and Matt were on the job.

The drain taking water east off the 7th fairway was completed and the drain running down the Sth side of the 8th was extended to run water into the bottom dam. Soil was also moved to the top of the 6th fairway. This is perhaps the wettest and boggiest area on the course/Park. Quite a bit of soil will be dropped here and levelled to run the water into the drain.

Along the way we uncovered the light red cable that runs to the 8th green and activates the decoder and also the blueline ring main. No damage done, Matt has a very fine touch with that very powerful machine.

The drain off the 7th Fairway takes shape.

The drain off the 8th fairway, behind the 8th green and in to the bottom dam is looking excellent

Mal Begins to fill in the trench covering the light red cable

The trench covering the blueline ring main is covered over.

Day 56 – Thursday September 17th

Mal, Tony L, Cam, Sevi, Andy 1, Andy 2, Bob, Freebie and Matt were on the job.

Two excavators, one finishing off the drain behind the 8th green and from behind the 5th green into the bottom dam. The other sorting the drain behind the 3rd green, around the 4th tee and into the drain to the bottom dam.

Along the way we decided that the drain works had rendered one path to the women’s 6th tee no longer viable so the new garden was extended. The treated pine posts had to be moved to cover the larger area, luckily we had a few spare, (thanks Rob Good) so no gaps in the boundary. Plenty of mulch to be moved in the trailer but, eventually, we did get smarter and have the bobcat load the little tipper to make things a little easiier.

By mid afternoon the excavators had moved to widening and shaping the spoon drain across the 3rd fairway and doing the same to the drain that runs across the 8th and 7th fairways. The tipper also carted a great deal of soil to the top of the 6th fairway, this area had to be raised by about 500mm so plenty of soil to be moved around by Andy 2 in the bobcat.

The drain around the 3rd green and behind the 4th tee is looking good. The spot for the grate to the pipe into the bottom dam is marked.

Filling and levelling behind the 8th green.

That’s the one we were looking for, the last load of mulch. Now, a few more plants and all will be good.

Day 57 – Friday September 18th

Mal, Tony L, Cam, Sevi, Andy 1, Andy 2, Hugh, Freebie and Matt were on the job.

After knocking the tops off all the high spots on the Sth side of the top of the 7th fairway Andy headed down to the 6th to level off and compact all the soil that had been dropped there. Still a fair few loads needed to finish off that job. Matt also pulled up a couple of old stumps that were blocking the drain on the east side of the 6th fairway. He cleaned out that drain so that it took water away to the large N/S drain on the eastern boundary

Andy 1 cut a pipe through from below the men’s 10th tee, this drain runs behind the 1st and carries all the water from the oval and the Recreation Centre. We will put a sluice gate in later so that, should there be a summer thunder storm, we can divert the run-off into our dams. Andy also cut pipe in behind the women’s 10th tee, this will help drain the 10th fairway. Last job for the day was to cut back and reshape the Nth mound on the top dam. This more gentle shape opens the fairway, allows us to fill a low boggy area and reduces the likelihood of a bad bounce into the rough.

The new drain from the men’s 10th tee. We will put in a sluice gate so that should we have a summer thunder storm we can direct that storm water down into our dams.

Water already running in the drain from the women’s 10th tee

Freebie and Sevi get the new mound on the 3rd green ready for sowing down.

Matt clears stumps and sorts out the drain at the Nth end of the 6th fairway

Day 58 – Monday September 21st

Tony L, Sevi, Hugh, Freebie and Bob were on the job.

Too wet and slippery for the big machines but the RGC team was not deterred. Plenty of things to be going on with.

First, finish the new mound on the 3rd, this mound will direct water into the new drain and also keep errant shots away from the 4th tee. Once Freebie was satisfied (he is “almost” a perfectionist) we were ready to sow down and smudge the seed in. Looked great, then a spot of rain to kick-start the seed.

Second, smudge the reshaped mound on the top dam (the reshaping runs water off the fairway into the dam). A few clumps were removed and then the pallet smudger went to work taking any high spots off and filling the low ones. Next spread and smooth out the sand and finally sow the seed and run over with the light weight screed. Again, job looked good and the rain fell just after we finished.

Sanding on the Nth side of the top dam ready to sow down

Shovelling and raking sand then sowing down – very strenuous work

Day 59 – Tuesday September 22nd

Tony L, Sevi and Freebie were on the job.

The top of the 7th fairway had been levelled and a few low “crab holes” filled in. So load up the bushman and the trailer, pack on the pallet smudger and the light wright screed, make sure the shovels and rakes are close to hand and that the seed is nearby then up and away. We had to add a spot of weight to the pallet smudger and once we got the equation right we just had to drive around and around, throw out the sand and then drive around again. Some could see this as a boring afternoon but we were surprisingly enthralled by the results. Next sow down and smooth over with the light screed.

Again, as we were repairing a broken rive chain on the cushman the rain pelted down. Good time to be back in the shed.

Again, hard yakka moving all that sand, certainly takes it out of you

This time we tried the mechanical seed spreader, looks easy but took some pushing.

This time we tried the mechanical seed spreader, looks easy but took some pushing.

Day 60 – Friday September 25th

Mal, Tony L and Matt were on the job.

After heavy rain overnight it was clear which drains had to be attended to next. The main one was between the 18th and 4th fairways and running behind the women’s 5th tee. This drain was originally designed to take water from the 18th fairway and around the green, over to the 4th fairway and then into the top dam. It had become a wet, boggy and a slippery area for all who use the Park. Tony and Mal had to cut and clear away some low and/or dead branches to allow Matt and his excavator in to clear and level the drain so that water actually ran. Heavy rain and hail fell during the morning and a spot of snow in the early afternoon

Matt keeps sorting out the drain.

Day 61 – Monday September 28th

Special thanks to Ron Walker who agreed to take responsibility for the expansion to the irrigation system works.

Ron, Freebie, Tony L and Sevi were on the job.

A pretty relaxed afternoon checking connection points and marking just where the new irrigation pipes were to run. Find existing joins, locate where existing pipe crosses fairways and mark well clear. Find the original blueline main and expose for new T-joins. Locate sprinkler banks on 4th and 16th and mark where new 40mm pipe will be cut in. With so much rain over the weekend the ground was soft so digging was not too difficult, just watch out for any RED Cable!

Ron & Tony find the blueline ring main (at the back) & the heavy red cable between the 2nd & the 5th greens.

Day 62 – Wednesday September 30th

Ron and Tony L were on the job.

With the trencher due on Thursday we had to uncover a few more connection points. The 40mm lines to sprinklers on the 4th and the 16th and connecting solenoids and decoders to fairway sprinklers on the 6th and 18th. Also connection points for the new 63mm E/W lines on the 4th and E on the 7th and W on the 8th.

Plenty of careful digging to expose the pipes and the red cable that actually makes the whole system operate.

East/West connection points for the 63mm line on the 4th

Day 63 – Thursday October 1st

Freebie, Ron, Tony L, Mal, Sevi, Elaine, Todd, Paul & Clive were on the job

Mal got down to work sorting out the 6th fairway. We had hoped the initial drainage works would take the bulk of the water away but after steady rains in recent days there were still many very wet areas. Once the sun moves and you get a clear look, stand back with Mal and Andy and have another look; the fairway was in fact concave. Either raise the whole area, many cubic metres of soil and many hours on the machine or a single drain down the middle and into the bottom dam. If necessary we can add in more herringbone drains into this main one. With around 30mm of rain predicted over the next four or five days this drain will immediately be important. Then another gentle spoon drain from the east of the 6th green into the large N/S drain on the eastern boundary. Finally a drain from the west of the 6th green into the new drain off the 7th fairway. All in all a big day.

Hobbs Drainage, Peter and Todd, turned up at 7.30am and were straight into it. Trenching in 63mm purple pipe from the sth of the 5th fairway across to the Nth of the 7th fairway. Then west up to behind the 16th green and east down to the 6th fairway. A second 63mm line from the 4th fairway, west to the blueline ring main near the 4th green and east to the blueline ring main between the 2nd and 5th greens. Two other lines were also cut in, 40mm greenling to the fairway sprinklers on the 16th fairway and 40mm greenline to the eastern most set of sprinklers on the 4th fairway. These larger pipes will see far greater pressure and more spread from all sprinklers. Along the way we only had a few accidents, two 40mm purple pipes were cut, two heavy red cables were cut and one 25mm greenling to the tee sprinklers, (5th and 12th tees). A quick call to Darren Newnham ad all was sorted, repairs to be done over the next few days.

We had a great morning tee and lunch, ta Elaine very much appreciated

All in all a very productive day.

Freebie and Clive change the old 63mm/40mm elbow for a 63mm to 40mm T-join

Water from the 8th fairway flows down the trench.

Andy trenches in the drain down the 6th fairway

Peter and Todd roll out the 63mm pipe, much easier than the way we did it in 2019!

Accident No 1, Freebie, Sevi & Clive (Rubber boots) repair the 40mm pipe between the 8th and 9th fairways before cutting in the 63mm pipe (Daz will repair the red cable later on).

Day 64 – Friday October 2nd

Freebie, Ron, Tony L, Mal, Wendy, Andy, Elaine, Jenny H, Paul, Todd, Hugh & Clive were on the job.

Mal and Andy removed a few stumps along the way as the excavator made its way down to the 6th to finish off the new drain. Then some work clearing and reshaping the drain and the mound behind the 18th to allow water to get into the drain and to provide better access for motorised buggies

Freebie and Clive just set about closing off all the pipes we had put in yesterday. There was one, quite complicated set of joins on the Sth of the 4th fairway. Two 63mm T-joins into the 63mm purple pipe, a 40mm join into the 25mm line running to the most easterly bank of sprinklers on the 4th fairway and a repair to the 40mm purple line. Took quite some time and a deal of shovel work to get just the right angle for each of the joins. The “Super Two” worked their way up and down the 4th fairway connecting as they went. The final join, a 63mm T-join into the 40mm blueline ring main at the bottom of the 4th fairway was completed just after lunch, then Freebie was off to cut the surrounds, they had grown quite amazingly over the last two weeks.

Paul trenched another bank of sprinklers on the bottom of the 18th and the bottom of the 6th. We got most of the pipe in but ran out if time to fit the sprinklers. Hugh and Ron were busy fitting the 40mm into the the bank of sprinklers and Mal and Tony fitted off the 40mm line into the bank of sprinklers on the 16th fairway.

Then Clive, Hugh and Ron turned on the water and set about inspecting each of the joins. Two leaks but a bit of work and they were fixed. The two cuts to the heavy red cable were also repaired.

Again, Wendy and Elaine had morning tea and lunch sorted with Jenny H dropping in to help out.

Freebie and Clive finally sort the “Big One” on the 4th fairway

Clive seals the deal with the final 63mm to 40mm T-join on the bottom of the 4th fairway

The new 40mm line into the sprinklers on the 16th fairway

The pipe, almost in the ground, for the new bank of sprinklers on the 6th fairway

The pipe, almost in the ground, for the new bank of sprinklers on the 6th fairway

Clive, Hugh and Ron set about checking for leaks

Clive, Hugh and Ron set about checking for leaks

Day 65 – Tuesday October 6th

Freebie, Tony L & Clive were on the job.

All the new joins had been under pressure for a few days so time to check them out to see if there were any leaks. Problem, plenty of rain so out with he sand buckets to empty any storm water and then wait to see if there were any drips. All in all we checked every new join, seventeen of them, and the good news was only two very slow leaks.

The 63mm to the 40mm blueline ring main beside the 4th green and the tricky one from way back in late 2019, on the Sth side of the 5th fairway. Pull them apart, check that pipe haas been fitted properly into the join etc. On one we had to hook Clive’s 4 X 4 to the pipe so we could insert an additional 10 – 15mm into the join. All ended well but we will leave the joins uncovered for a day or so to just make sure.

Freebie and Clive sort out the join near the 4th green.

That obstinate join from 2019 gets its comeuppance.

Day 66 – Friday October 9th

Clive, Freebie, Hugh, Tony L, Sevi & Mal were on the job. Sevi spent most of the day mowing the tees and grassy mounds. A big job, especially after the heavy rain and with so much of the grass getting that spring burst of growth, so both tall and wet.